- WITTENSTEIN North America

- Products

- Galaxie® GS

Galaxie® GS

The Galaxie® GS is a compact, configurable, zero backlash gearbox with hollow shaft and input drive flange.

- Your benefits

- Technical data

- Options

Configurable, backlash free gearbox with hollow shaft and flange input interface

Advantages

- Configurable gearbox

- Highest torque density

- Extreme torsional rigidity

- Maintenance free

- Improved true running

- Robust and precise output bearing

- True zero backlash

- Easy integration into machine design

Benefits

- Increased productivity

- More stable processes

- Achieve higher performance machine designs

- Greater competitiveness

- Reduced commissioning time and costs

| Galaxie® robustness line | Galaxie® accuracy line | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | Unit | 110 | 135 | 175 | 120 | 190 | 300 | |

| Variant | GS | GS | GS | GS | GS | GS | ||

| Outer diameter1 | D [mm] | 160 | 191 | 241 | 122 | 193 | 304 | |

| Hollow shaft diameter | d [mm] | 33 | 45 | 57 | 44 | 72 | 117 | |

| Length2 | l [mm] | 145 | 161 | 213 | 83,6 | 128,5 | 183 | |

Max. acceleration torque3 | T2B [Nm] | 1086 | 1800 | 4050 | 350 | 1500 | 6000 | |

| Max. output speed3 | n2max [rpm] | 95 | 80 | 61 | 125 | 80 | 50 | |

| Nominal output torque3 @ n2N | T2N [Nm] | 450 | 750 | 1685 | 190 | 750 | 3000 | |

| Nominal output speed3 @ T2N | n2N [rpm] | 23 | 20 | 15 | 60 | 40 | 25 | |

| Emergency stop torque3 | T2Not [Nm] | 3000 | 5400 | 12000 | 700 | 3000 | 12000 | |

| Torsional rigidity3 | Ct21 [Nm/arcmin] | 370 | 650 | 1400 | 155 | 625 | 2500 | |

| Max. input radial load | F1Q(SF1) [N] | 2150 | 4500 | 5850 | 600 | 1980 | 4100 | |

| Ratio4 | i | -24 | 31 | |||||

Sizes 085 and 215 on request

1 Without connectors/varies depending on mounting position

2 Without cooling connectors

3 Values are subject to variations

4 With negative gear ratio, output turns in opposite direction to input; with positive gear ratio, output turns in same direction as input

Galaxie® robustness line series: Technical data valid without water cooling

Galaxie® accuracy line series: Technical data valid with water cooling

Technical data for reference only

Note

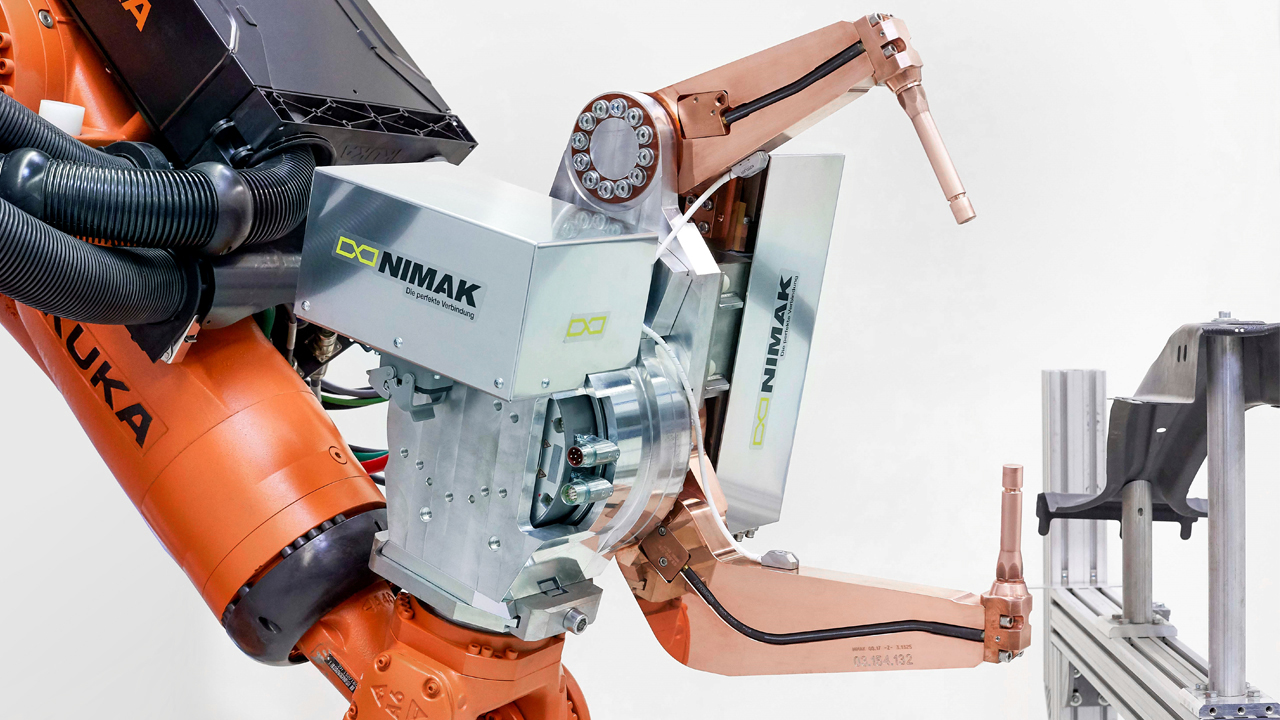

Drive possible by belt input with parallel motor mount or direct drive motor mounting. Customized variants also available for sizes 085 and 215 on request.

Typical applications

A/B/C axis for precise positioning in CNC applications like milling and turning or indexing tables.

Galaxie® GS