Accelerate Machine Design for Packaging, Processing & Converting

Machine designs for production of food, pharmaceutical products, medical textiles and personal care products require significant planning and knowledge. Food and beverage machines must account for hygiene and cleanability in processing and packaging. Pharmaceutical production demands high production quality with high throughput. Non-wovens and paper converting have to accommodate multiple motions in finite space. And critical considerations for environment, energy, precision, and safety must be balanced with speed, economy and other methods to minimize cost of ownership.

Proof of Concept: See how we combine application expertise with product performance for exceptional outcomes in Packaging, Processing and Paper Converting applications. Then contact us today to start planning your next project.

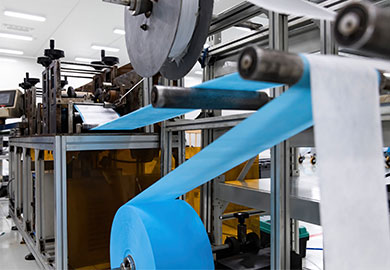

Converting Machinery:

High Speed, High Duty and High Reliability

Rapid availability of configurable components combined with sizing expertise results in high repeatability.

Expertise

Challenge: Non-woven converting machine builders must meet surge in demand, utilize new non-woven materials, and move quickly for competitive advantage.

Solutions: Starting the project with cymex® sizing software enables the simple dimensioning and evaluation of the complete drive train (application + transformation + motor + gearbox).

- Configurable components for quick retrofitting to existing machines.

- Specially designed gearboxes that operate at continuous, high speed duty cycles with no leakage.

Results: Rapid production time and enhanced performance. Low backlash and uniform performance of gearboxes ensures consistent, zero vibration motion, for a higher quality end product.

Performance

Featured Product:

- Sizing Software for configuring complete drive

Other Performance Areas

- Melt-blown Converting

- Non-woven Converting

- Poly and Laminate Converting

- Paper Converting

- Medical Mask Manufacturing

- High Repeatability

- UV Curing

- Laser Cutting

- Ultrasonic

- Disposable Glove Machine

- Converting Machinery

- Slitter Rewinder

- High Production Capacity

- Sheeting & Stacking

- Core Cutting Machines

- Razor, Shear, Score and Hot Knife

- Slitting Machines

Related Products

Processing Machinery:

Dosing 6 Million Per Day with No Waste

A huge benefit was online access to the dosing stations for servicing and optimization.

Expertise

Challenge: Dose liquids of varying viscosity into pads precisely and efficiently.

Solution: Small servo drives (40mm diameter) with a ratio i=30.67 are installed in two dosing stations with a compact servo drives featuring IP20 protection and a ProfiNet interface. Full stainless steel was chosen to protect equipment from corrosion from product leaks and allow for external cleaning.

Results: Precision with individually scalable drives that are high performance and future proof.

- Up to six million doses per day with zero waste of dispensing material

- Repeatable precision ensures uniformity AND reliability

- Dosing by a linear driven valve or a rotary driven screw

Performance

Featured Product:

Small Servo Drive System in Corrosion Resistant Design

Other Performance Areas:

- Dosing

- Conveying

- Capping

- Sealing

- Agitators Chillers

- Centrifuges Dryers & Granulators

- High Pressure Homogenizers

- Mixers

- Spray Coating

- Sifters

Related Products

Packaging Machinery:

Filling and Packing 4 Bags Per Second

Use of a WITTENSTEIN rotary actuator allowed for filling and packaging 250 cycles per minute, producing 4 bags per second.

Expertise

Challenge: Maximize speed with minimal footprint in a continuously running vertical tubular bag machine. Precision must be maintained - application welds packaging foil to form a tube, capture free-flowing product, then weld package closed to seal. Conventional motor/gearbox units are too big, too heavy and not dynamic enough to achieve desired cycle times.

Solution: Using a rotary servo actuator connected directly to the jaw closer for precision, speed and compactness. With its high dynamics and low weight, our drives make cycle times of up to 200 cycles a minute possible. In addition, the low weight allows for a reduction in drive power in the jaw stroke.

Results:

- Sealing jaws open and close 250x per minute

- Welding takes 70 milliseconds

- Entire bag process takes 250 milliseconds

- Four bags can be completely filled and packaged every second

Performance

Primary Product:

Rotary Actuator

Other Performance Areas:

- Blister Packaging

- Vaccine Packaging

- Personal Care Packaging

- Continuous Band Bag Sealing

- Powder Auguer

- Filling Machine

- Flow Pack Wrapper

- Label Applicators

- Case Packers

- Air Cushion & Pillow Systems

- Stretch Wrap Systems

- Micro Liquid Fillers

- Filling & Closure Systems

Related Products

Request more information

SIZING TOOLS

All success stories start with sizing. Our software portfolio helps you choose the right drive:

Retrieve CAD data for your specific gearbox

- CAD data for all types of gearboxes

- Performance data and dimension sheets

- Search via ordering code

- Available online without logging in

Find the right gearbox online

- Efficient gearbox selection in seconds

- Access by specifying application or motor

- Direct request for quotation

- Available online without logging in

Size the entire drive train in detail

- Detailed calculation of complete drive trains

- Precise simulation of motion and load variables

- Desktop software for complex designs