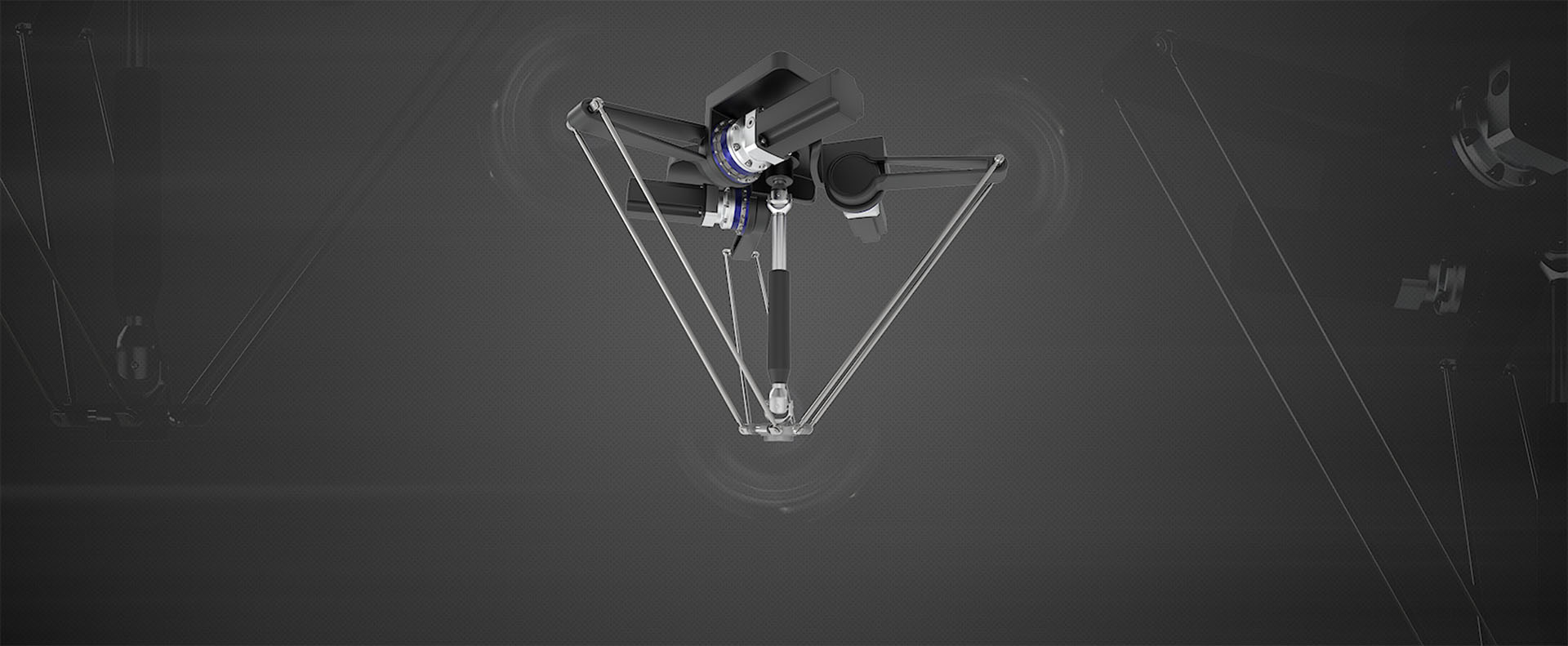

Gearboxes and actuators for Delta robots

The right solution for all requirements

Varying customer requirements create major challenges for Delta robots and require continuous further development of the drives. For more than ten years, WITTENSTEIN has been developing and manufacturing gearbox and actuator solutions for Delta robots that are just as individual as the applications of our customers. With unique engineering experience, recognized methodological competencies and software expertise as well as a high-performance product portfolio, we offer our customers the security of a technically and economically refined drive design for highly dynamic, multidimensional movement profiles. Our success story is continuing with an extended product portfolio and new individual drive solutions for your robot concept.

The varying requirements of machine users and construction companies create major challenges when developing robot concepts.

This has an effect on the machine design and component selection.

WITTENSTEIN can supply an array of drive solutions for your Delta robots, depending on the design and application.

Use of an actuator further reduces inertia.

Constant backlash throughout the service life of the gearbox ensures a consistently high performance.

Highest quality standards guarantee a long service life and extend maintenance intervals.

High speeds increase machine output

Minimal backlash and extreme rigidity ensure maximum positioning accuracy at the tool center point.

Extremely reliable gearboxes prevent cost-intensive machine breakdowns

Tell us what you’re looking for, and we’ll support you with technical data, CADS, sizing assistance, application insights and more. No strings attached.